Reaction Injection Molding (RIM) Applications

The applications for reaction injection molding (RIM) are very extensive due to the number of polyurethane material system formulations available to mold with. Applications for RIM are usually those with low annual production volumes associated with them. Usually these can range from 200 units per year up to 20,000 units.

Industries with Applications for Reaction Injection Molding

Industries with applications for RIM molding include:

-

Medical & Healthcare

-

Automotive

-

Electronics

-

Aerospace

-

Marine

-

Construction

-

Sports & Recreation

-

Consumer Goods

-

Various Other Industries

Common Applications for Reaction Injection Molding

Typical applications for RIM molding include:

Medical Device Covers

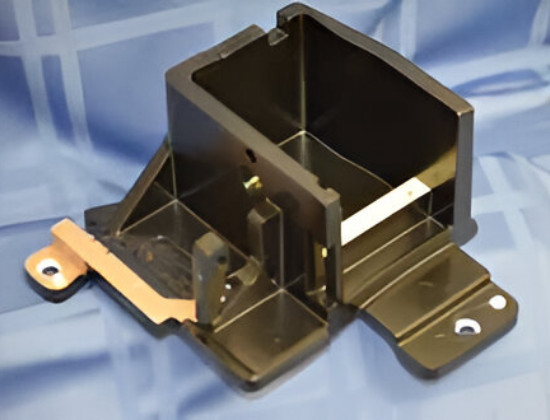

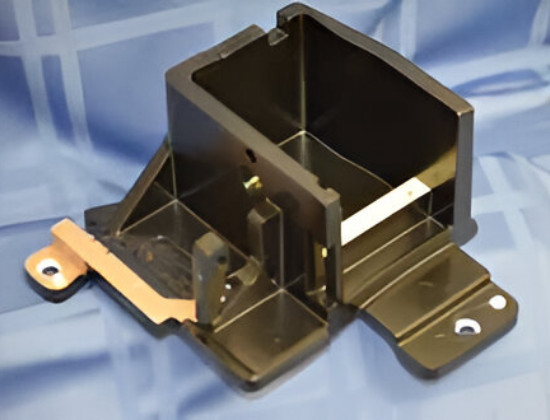

Device or Electrical Enclosures

Housings

Structural Parts

Bumpers

Spoilers

Interior Trim Components

Panels and Doors

Specialized Parts

Heavy Equipment Consoles

Electronic/Glass Encapsulation

Analytical Machines

Carts

Boat Components

Recreational Vehicles

Sporting Equipment

Furniture

Appliance Parts

Tool Handles

Specialized Applications for Reaction Injection Molding

-

Large Component Manufacturing

-

Products Exposed to High Temperatures

-

Products That Need to Be Durable

-

Products That Need to Be Chemically Resistant

-

Products with Complex Parts

-

Products with Varying Wall Thicknesses

-

Products with Encapsulated Parts

-

Products That Benefit from Fewer Parting Lines

Recent Reaction Injection Molding Applications from Thieme

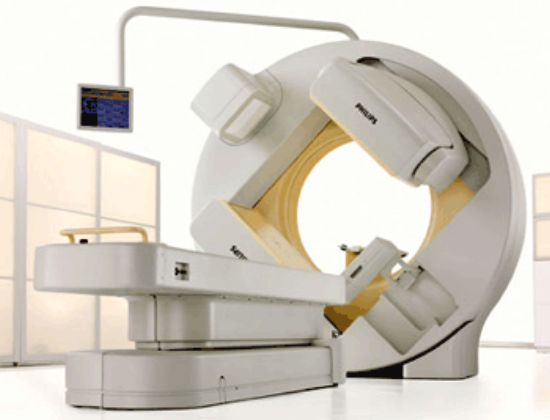

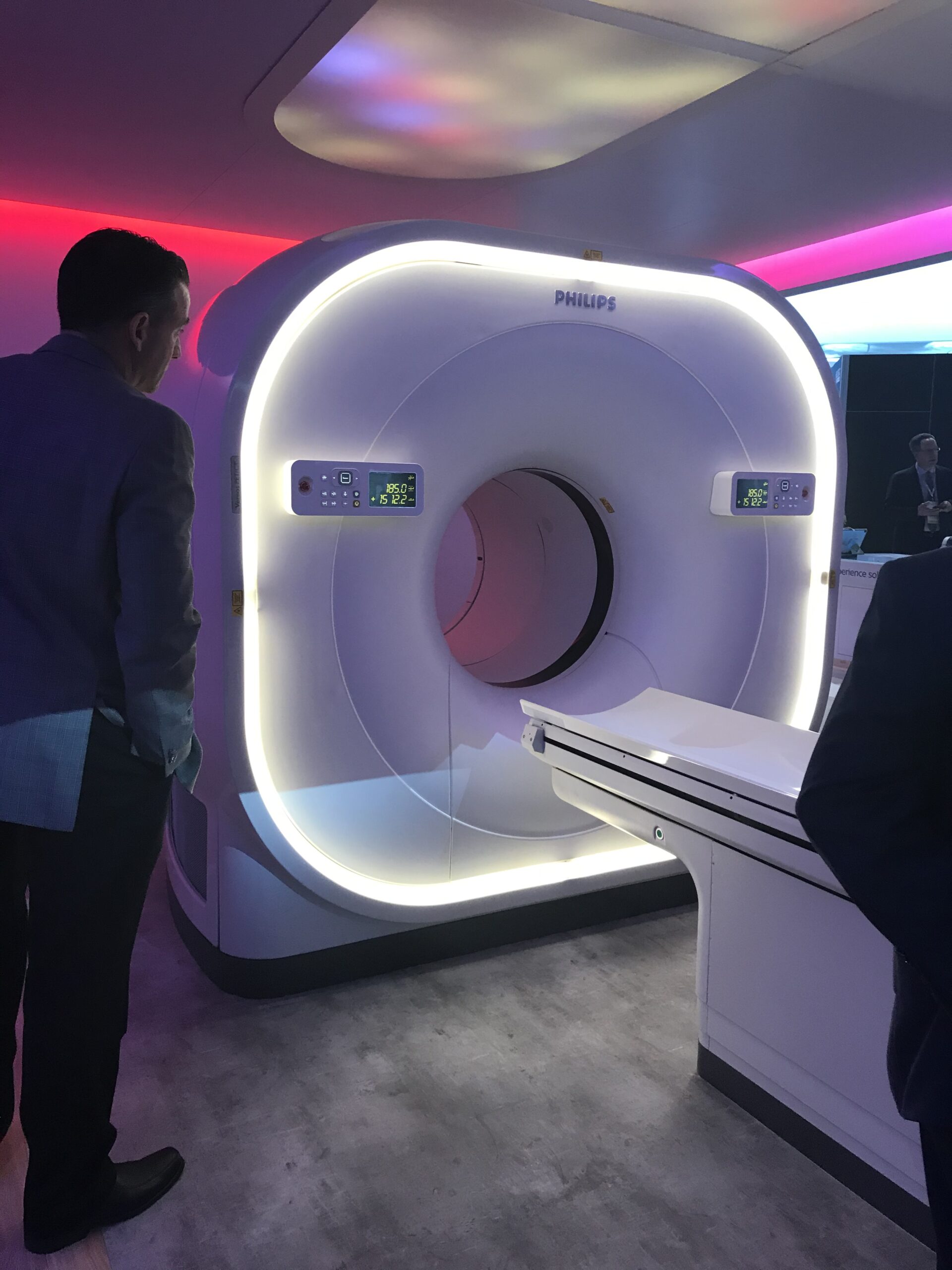

Philips CT/PET Scanner

Translucent Light Ring with High Gloss Finishes

Covestro Prism CM-200 PUR Parts up to 7’ x 7’

Volvo/Prevost Luxury Motorcoach Bumper

Elastormeric PUR Nearly 10’ long, single shot

MarCor Water Purification Cart

Molded in a single Shot Baydur 726

4’ x 3’ Complete Assembly at Thieme

Segway Three Wheel Police Patroller Body

Four Parts Elastomeric Bayflex PUR

Leverage Custom Reaction Injection Molding for Unique Applications with Thieme

Thieme specializes in custom reaction injection molding solutions for a wide range of devices, industries, and applications. With our cutting-edge RIM technology, in-depth tooling expertise, comprehensive process knowledge, and responsive service, we are proud to be a reliable provider of both large and small format molding solutions for our global clientele.

Are you ready to explore the benefits of reaction injection molding for your unique application?

Our dedicated full-service team is ready to support you throughout every phase of your upcoming RIM project, from initial conceptualization and strategic planning to seamless production and fulfillment. Reach out to us today for a consultation and learn more about how your application can benefit from our RIM services.