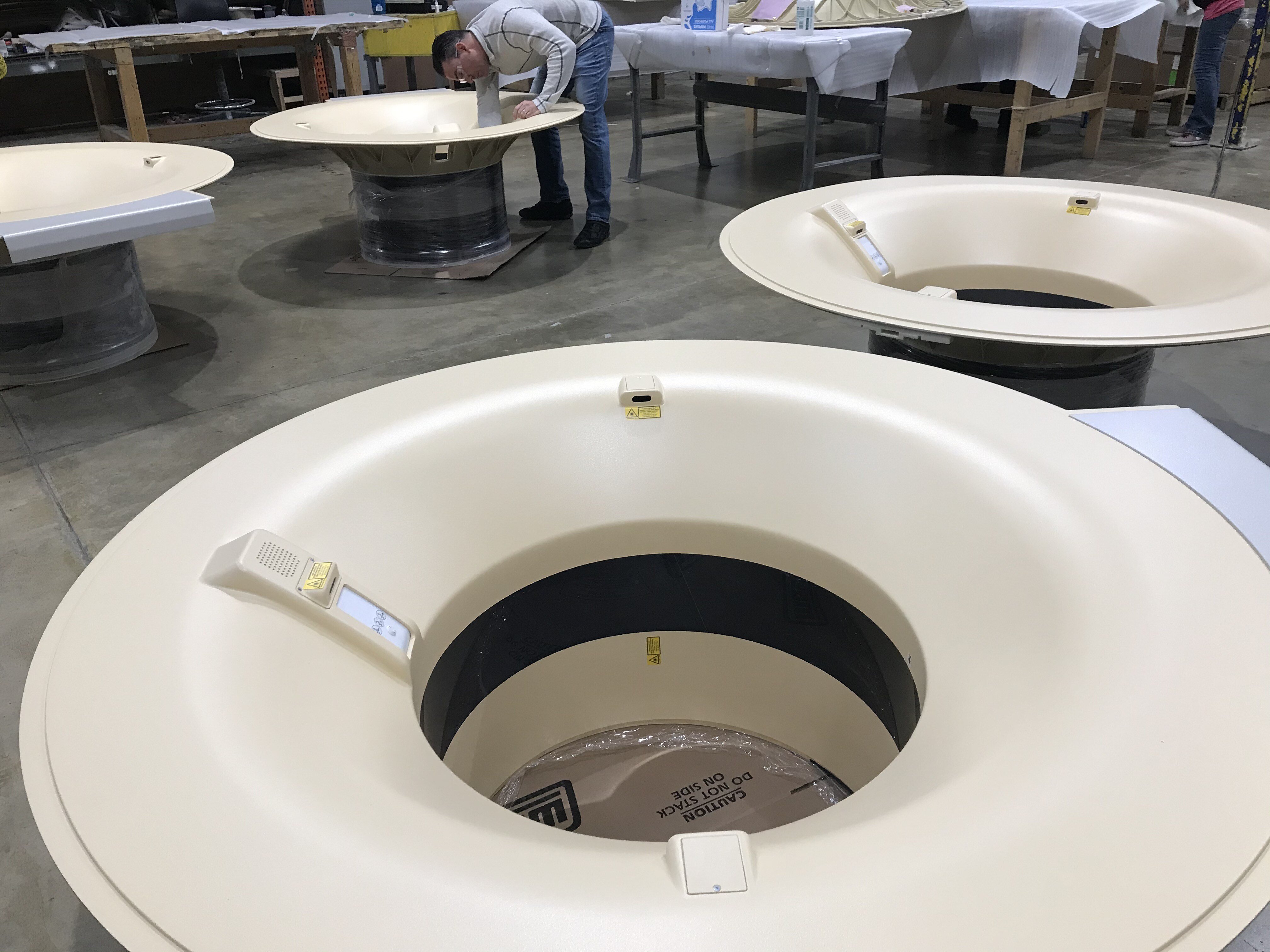

RIM Encapsulation

Encapsulation is a process also known as over-molding, and it’s one of the best methods for adding strength, stiffness, and function to finished products.

Thieme uses polyurethane during the encapsulation process because it has a lower molding temperature than most other molding materials. Since the RIM process is a gravity-fed, low-pressure, and low-temperature molding process it will not adversely affect RF signals, PCB boards, or solder joints. Additionally, when looking to add strength to a PUR molded part/assembly, metal inserts can be molded into the part during the molding process. Brass inserts, glass assembly hinges, pins, magnets, and a host of other components can be encapsulated into the final part using PUR and the RIM process.