Technology Videos

Economic Advantages of Reaction Injection Molding

Technology Videos

This video shows reasons why our process should be used for plastic molded enclosures and structural parts. It shows the THIEME process for molding and how it works. It highlights the concept, tool design, manufacturing, post mold, paint and logistics activites of the entire process. Follow a part from concept through to production.

Thieme Corporation Applications

This video shows many product applications for Reaction Injection Molding. Plastic molded enclosures, housings, panels, covers and structural foam parts made using polyurethane foam material systems. Parts are for a variey of industries including medical, automotive, energy, analytical, scientific, heavy equipment and construction.

Polyurethane (PUR) V1 0001

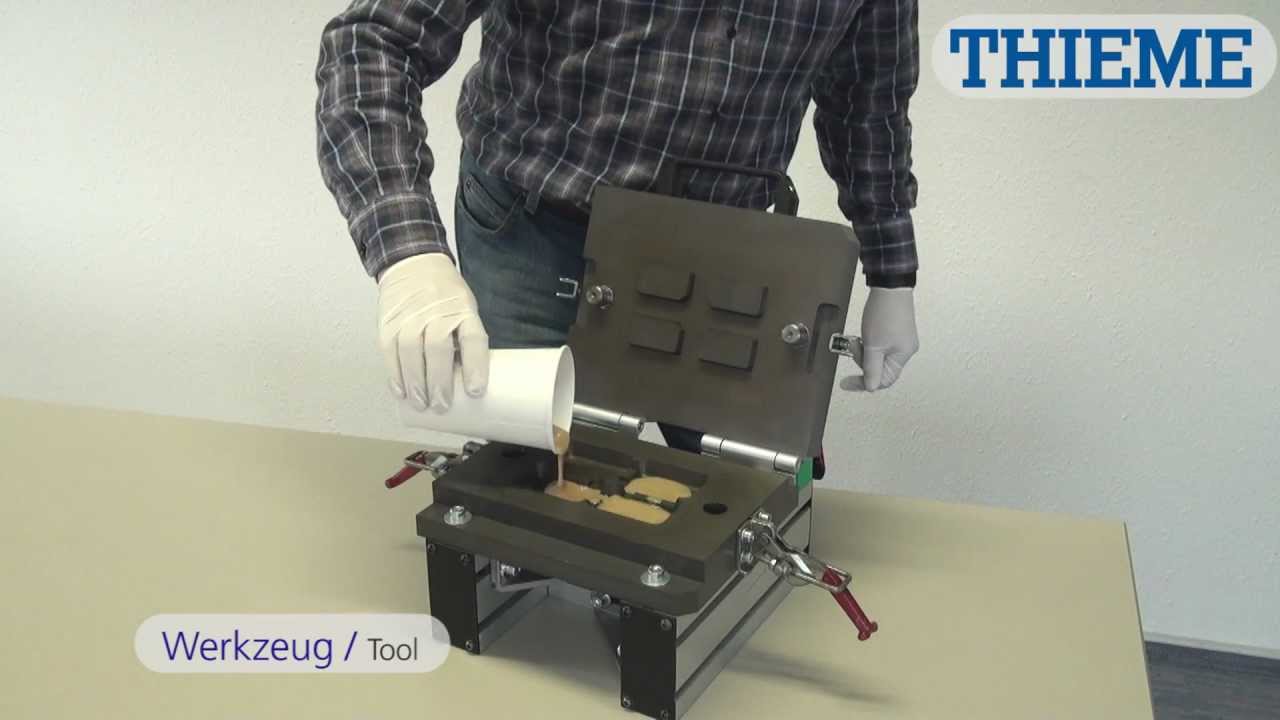

This video captures the many commercial and industrial applications using various polyurethane foam systems. Shows the open pour injection method for automotive rigid parts and also highlights the closed injection method used to make large format parts including device enclosures, housings, covers, panels and other structural parts.

PUR materials allow designers to make very large one-shot parts, parts with varying wall thickness and also enables the designer to design function and aestetics into both sides of the part.

This offers many more advantages than thermoforming or fiberglass lay up technologies. Using low cost aluminum tooling, Thieme can make your low annual volume production runs (100-10,000 parts) a success.

Reaction Injection Molding (RIM)

Basic molding Operation showing rigid light density foam encapsulation of metal inserts for an automotive application (EA knee bolster). Use of robot technology and several endforms are used. The video shows the basic premise of polyurethane foam molding. We specialize in large format molding and have capabiliy to make single shot parts up to 75 lbs in a single shot (or 10′ x 8′ x 3′). With our higher density foam systems, such as Prism, Bayflex or Baydur products, this is an excellent process for medical device enclosures, analytical housings and structural parts needing low annual volume production (200-20,000 parts per year). This video shows an automotive part that is mid to high volume in annual use (1000-1,000,000 parts per year).

Polyurethane Reaction

This video shows you the basic reaction required to make any polyurethane foam system whether it is a solid system, rigid foam, elastomeric, acoustic or sound absorbing foam. The two component process is the same.

THIEME PUR Production

This video shows you the production of a molded part using our process and polyurethane material systems Baydur 726, Prism CM-200 and Bayflex, all structural polyurethanes used in the medical industry.