Reaction Injection Molding vs Injection Molding

There are many different ways to manufacture plastic parts. Reaction injection molding (RIM) and Injection molding are two popular alternatives; however they seem to often get confused. Let's take a look at what they are and what their differences are.

What is RIM Molding

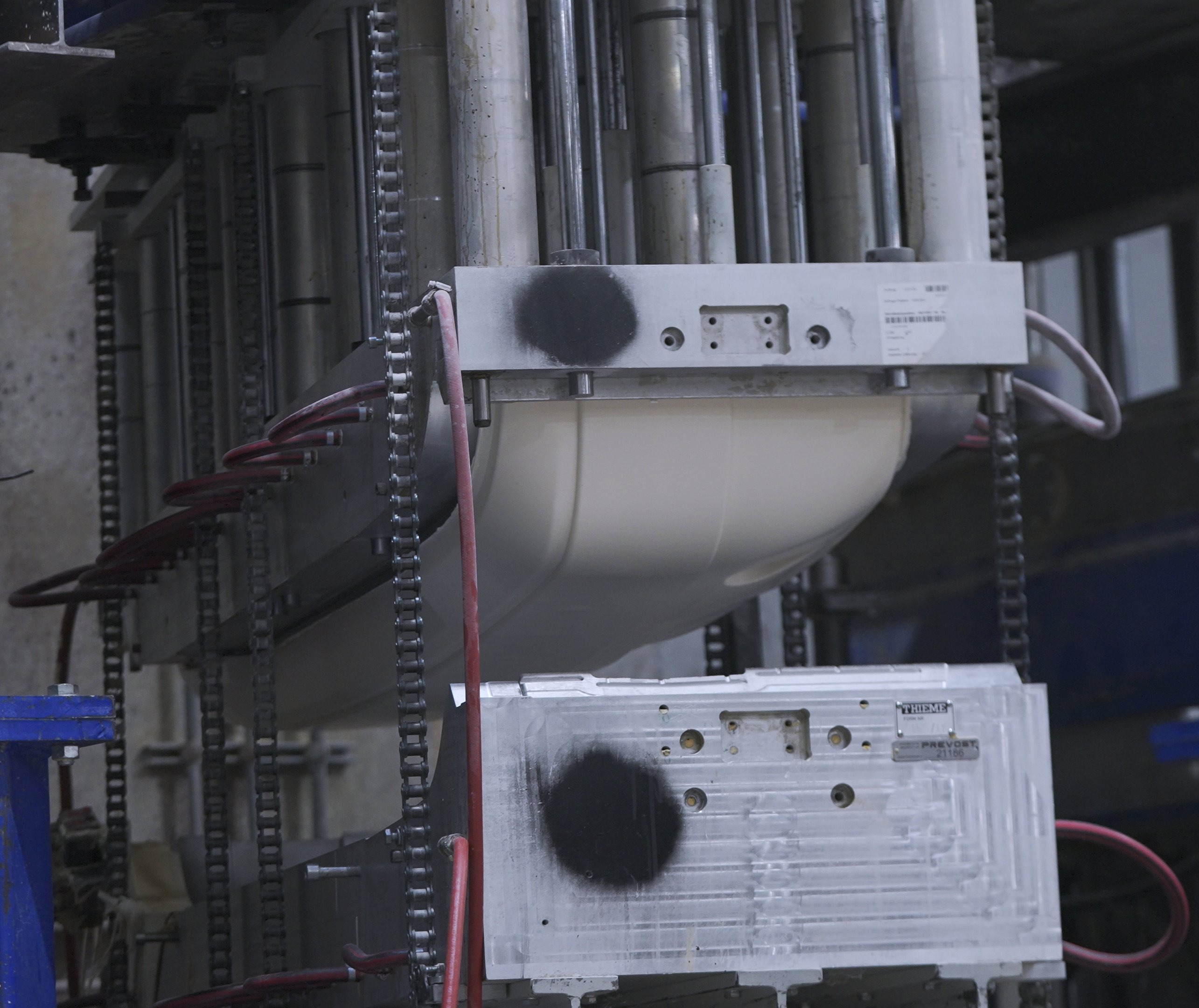

RIM Molding is the process of producing parts out of thermoset foam. A thermoset is a molding resin that is involved in a chemical reaction, similar to epoxy glue. There are two parts, a polyol and an isocyanate, when mixed and meet a heated tool surface, they will undergo a chemical and exothermic reaction and eventually set up. The mixture is injected under low pressure and allowed to expand and cure inside the mold. Once molded or cured, this type of material cannot be melted down and reused as typically seen in the thermoplastic world of traditional injection molding. There are many other molding processes that use thermoplastics such as thermoforming, extrusion molding, compression molding, and roto molding among others.

What is Injection molding?

Injection molding is the process of melting down a thermoplastic resin through a barrel and screw process and then, under pressure, pushing the plastic into a mold to basically form a shape. Yes, it can be more complicated than that. However, this process is the most common method for quickly producing high volume, low cost plastic parts and allows some very complex plastic parts to be manufactured.

Similarities of injection Molding and RIM Molding

There are many similarities between these two processes. They both are very repeatable, meaning that you will achieve the same consistency over and over again within the tolerances specified. This allows for mass production without a lot of variances. Both methods produce parts that are adaptable for a variety of industries because they can easily be mass produced. Each process can give you the physical aesthetic required.

Each process can be used with various materials. This means that the finished parts can be produced out of materials that will meet certain criteria and specifications for that particular need. Some parts, for example, might need to be heat or moisture resistant, while others may need to have superior wear characteristics.

Within both processes, there are insert molding options. This means that you can put in a piece of metal for example and mold around it. Think of the end of a plug and how the plastic contains the metal prongs within it. That is an example of an insert molded component using an injection molding machine. But, it can be done on RIM parts as well.

The Key Differences of RIM Molding and Injection Molding

- Injection molding applications tend to have higher part volumes associated with it whereas RIM Molding serves lower annual production runs.

- Injection molding has a very quick cycle time whereas RIM Molding has a much slower cycle time.

- Generally speaking, injection molding allows for in-mold color as the thermoplastic materials are precolored prior to melt. RIM materials are generally painted after molding as the PUR materials do not come pre colored.

- Injection Molding can employee lower per pound cost raw materials. RIM materials are engineered polymers and are more expensive.

- RIM tooling is made using aluminum and will provide a customer a 20-30% savings on tooling versus traditional injection molds that require proper shut offs and steel tooling due to the higher injection pressures used.

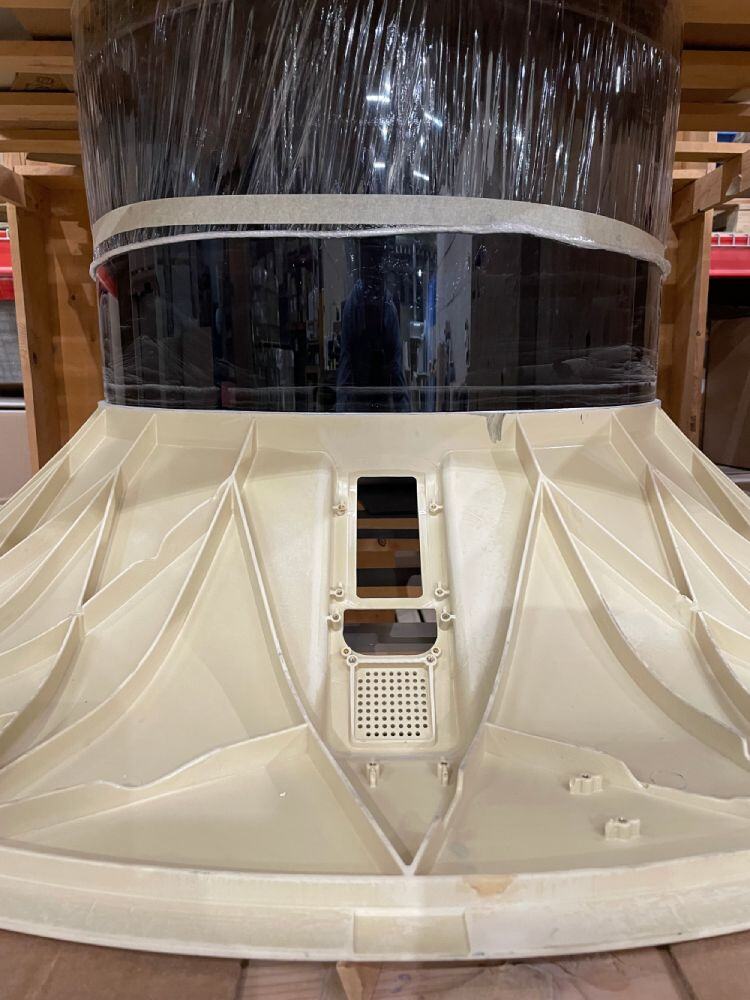

- The RIM process uses much less pressure than traditional injection molding. Coupled with the PUR foam nature of the process, larger parts can be produced using RIM. The larger the part in injection molding means a larger machine and the part cost will increase due to the pressures needed for larger parts.

RIM Molding advantages

RIM molding does have advantages over Injection molding. Since the RIM process employs the exothermic reaction of the materials and creates a foaming process vs a molten process as in injection molding, with RIM, you can have variable wall sections within the same part with experiencing sink, show through or distortion in the part. Traditional injection does not allow for this.

RIM enables manufactures to design very large single shot parts up to 8’ x 8’ x 2’ due to gravity fed, low pressure process. Although possible in traditional injection molding, machine cost and size both increase as the size of part increases.

Tooling cost is less with RIM molding vs traditional injection molding due to the materials used and the design considerations required for the traditional injection molding pressures.

Post a comment